Mold precision directly impacts final product consistency, surface quality, and production stability, while mold lifespan is critical to cost control. Among mold processing technologies, Electrical discharge machining is a core precision machining method due to its non-contact advantages. It outperforms traditional mechanical machining in complex precision mold production, enabling breakthroughs in high-end mold localization in China.

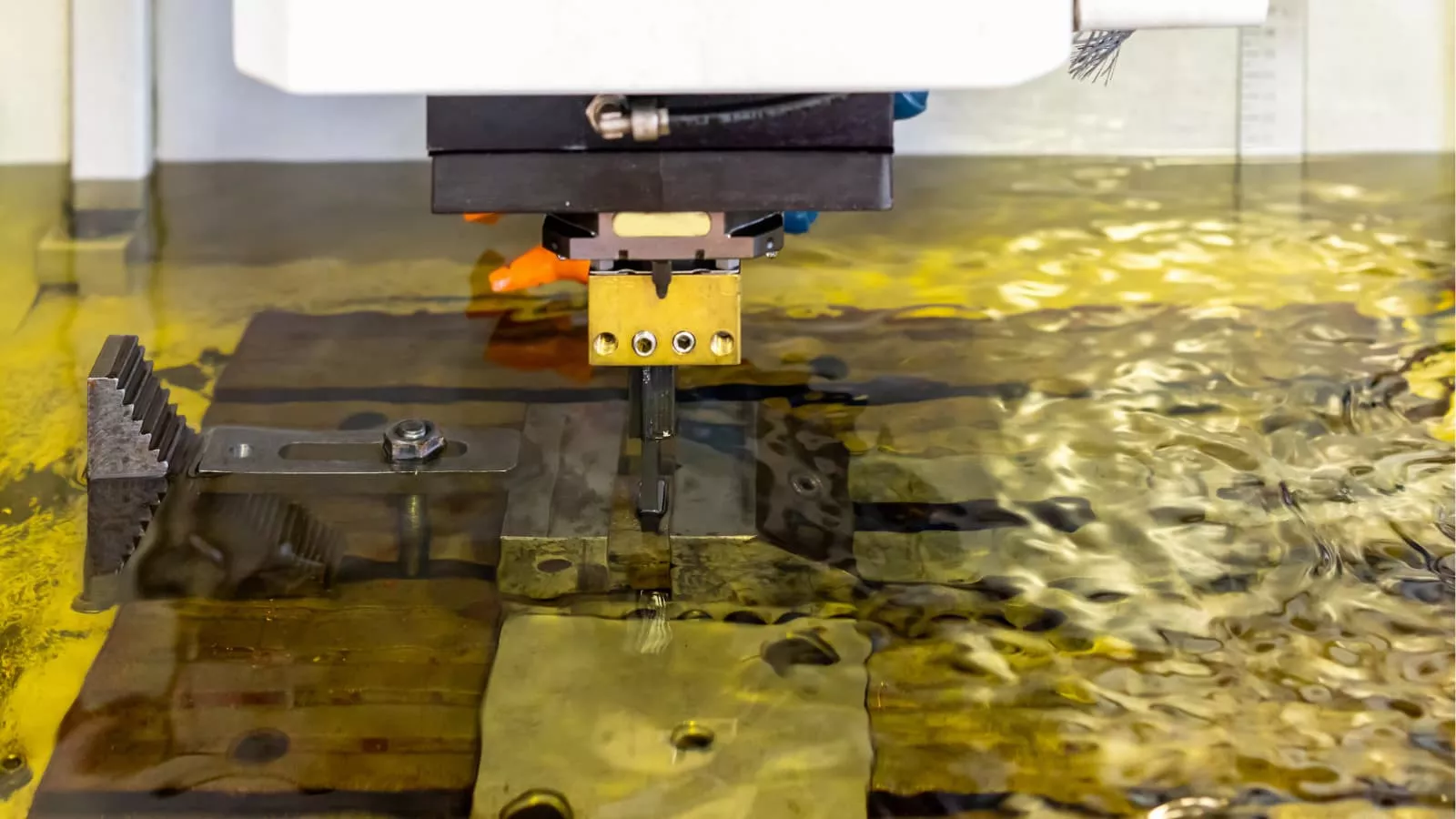

EDM operates on the pulse discharge erosion principle, which involves 4 key steps: First, an insulating medium, typically kerosene or deionized water, is used between the tool electrode and workpiece, with a servo system maintaining a 0.01 to 0.1mm discharge gap. Second, a high-frequency pulse power supply creates a plasma discharge channel when the electric field exceeds the medium's breakdown threshold. Third, 10,000 to 12,000℃ temperatures in the channel melt/vaporize local metal, forming micro-craters. Finally, the medium flushes away eroded material, and electrode feeding forms a precision structure matching the electrode shape. This non-contact approach eliminates mechanical stress, vibration, and tool wear, handling HRC50+ materials that challenge traditional methods.

Precision molds often have deep cavities, narrow slots, micro-holes, or undercut contours, features hard to machine via milling or grinding due to tool rigidity or accessibility issues. Electrical Discharge Machining uses shape replication: a complementary electrode enables precise shaping via discharge erosion. For mobile phone 3D glass hot-pressing molds, copper electrodes machine 0.5mm-radius grooves, 0.15mm spacing micro slots, and micron textures in one pass with tolerance of ±0.002mm. It also solves 0.8mm×12mm narrow slot machining for automotive panel dies, avoiding milling tool breakage.

Modern EDM equipment achieves nanometer-level feed control. With high-precision pulse power optimization, key dimensions are held to ±0.005mm, meeting optical and semiconductor mold requirements. Three technical pillars enable this: grating ruler closed-loop servo for feed error correction, adjustable pulse width for precise erosion control, and adaptive systems that adjust parameters to prevent over-erosion. Optical lens molds, for example, reach ±0.003mm cavity tolerance and λ/5 (λ=632.8nm)surface accuracy without post-grinding.

A "rough-semi-finish-finish" EDM process achieves Ra 0.1-Ra 0.8μm surface roughness. This meets optical/medical mold demands and cuts polishing time: injection mold cavities require just 2 to 4 hours of polishing post-EDM, vs. 20-30 hours after milling. Die casting molds benefit from EDM's micro-rough surface, which reduces sticking and extends lifespan by 30%.

EDM excels at thin-walled and micro-molds, avoiding deformation via non-mechanical processing. It only requires material conductivity, processing magnetic and semiconductor materials for new energy and electronics industries.

Electrodes act as replication benchmarks, so material selection and precision are critical. Copper suits finishing/complex shapes; graphite fits roughing/large cavities. Ultra-precision uses copper-tungsten. Manufacturing involves UG/Mastercam modeling, high-speed milling, EDM finishing, and laser inspection. Complex molds use multi-electrode strategies: roughing electrodes prioritize speed, finishing electrodes prioritize precision.

Core parameters like pulse width, interval, current, gap follow the "efficiency-precision trade-off" principle: roughing uses large pulses/current for speed; finishing uses small pulses/current for quality. Modern equipment has intelligent parameter libraries that auto-match settings and adjust via real-time discharge monitoring. This reduces operator reliance, such as correcting pulse intervals for gap anomalies or compensating for electrode wear.

Monitoring prevents failures from medium contamination, wear, or deformation:

1) Discharge monitoring detects arcs and adjusts parameters to avoid burning;

2) In-machine probes inspect dimensions post-segment;

3) Medium purity/temperature/pressure are controlled.

Ultra-precision molds use laser interferometers and finite element analysis for process-measure-compensate closed-loop control, reducing aero-engine blade mold error from ±0.005mm to ±0.002mm.