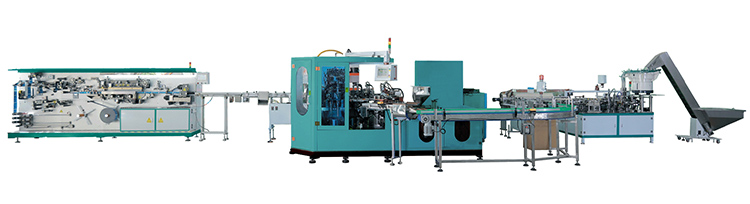

In today’s packaging industry, efficiency and precision play a huge role in creating high-quality tubes used for cosmetics, toothpaste, pharmaceuticals, and more. A laminated tube making machine is an essential piece of equipment that helps manufacturers produce smooth, durable, and visually appealing tubes. These machines combine layers of plastic and aluminum to create packaging that is both flexible and strong. Choosing the right machine can make a big difference in production speed, cost, and product quality. Understanding what features to look for before purchasing is important for any business aiming to stay competitive and meet modern packaging demands.

When selecting a laminated tube making machine companies should focus on performance, durability, automation, and user-friendly design. These machines come in various models, each offering unique specifications for speed, material compatibility, and tube size options. Investing in a high-quality machine ensures consistent output, better sealing performance, and long-term cost savings. Let’s explore the top features that matter most when buying one.

Modern laminated tube making machines are equipped with advanced automation systems that improve accuracy and productivity. Automation reduces human errors, maintains consistent quality, and allows for higher production rates. With automated control panels, operators can easily adjust settings such as tube size, layer thickness, and sealing temperature. This results in more uniform products and fewer defective tubes.

Machines with intelligent control systems also offer real-time monitoring and troubleshooting options. For example, if there’s an alignment or temperature issue, the system can alert the operator immediately. This not only prevents downtime but also minimizes material waste. Businesses that invest in automation can save time, reduce labor costs, and improve product consistency — all crucial factors for scaling production efficiently.

Speed is another critical factor when choosing a laminated tube making machine. In competitive industries, manufacturers must meet tight deadlines without compromising quality. High-speed machines are designed to handle large orders efficiently while maintaining precision. Some advanced models can produce thousands of tubes per hour, making them ideal for companies with high-volume demands.

Moreover, speed should always come with stability. Machines that can maintain high output rates while keeping uniform wall thickness, perfect sealing, and smooth finishes are worth the investment. This balance ensures consistent production without frequent maintenance interruptions. Therefore, high-speed capability combined with reliability is a must-have feature for any modern packaging facility.

A top-quality laminated tube making machine should be versatile enough to handle different materials and sizes. The ability to process various laminate combinations such as aluminum barrier laminates (ABL) and plastic barrier laminates (PBL) allows manufacturers to meet diverse market needs. This flexibility means the same machine can produce tubes for cosmetics, pharmaceuticals, or food packaging without major adjustments.

Versatility also extends to tube sizes and shapes. Machines that can adjust to produce tubes of different diameters and lengths provide greater flexibility for manufacturers. This helps companies serve a wider range of clients and adapt quickly to changing market trends. Ultimately, a versatile machine ensures long-term usability and better returns on investment.

Sealing and cutting are two of the most crucial processes in laminated tube production. A laminated tube making machine with a precise sealing and cutting system ensures that each tube has perfect edges and leak-proof seals. Advanced sealing technology also enhances the overall appearance of the tube, giving it a smooth finish that appeals to customers.

Accurate cutting mechanisms prevent material wastage and maintain uniform tube lengths. A good machine will feature automated sensors and alignment tools to ensure every cut is clean and exact. This attention to detail not only improves aesthetics but also enhances the structural integrity of the tube. In short, precision in sealing and cutting is a key factor for consistent quality output.

With rising energy costs, an energy-efficient laminated tube making machine can greatly reduce operating expenses. Modern machines are designed to consume less power while maintaining optimal performance. This makes them both eco-friendly and cost-effective in the long run. Energy efficiency also helps businesses meet environmental standards and improve their overall sustainability efforts.

Low maintenance is another essential feature to look for. Machines made with durable materials and high-quality components require fewer repairs and less downtime. Many new models come with self-lubricating systems and easy-to-replace parts, which help keep maintenance simple and quick. Investing in a low-maintenance machine saves both time and money, ensuring smoother production cycles.

A laminated tube making machine should be easy to operate, even for less experienced workers. A user-friendly interface allows operators to monitor production data, adjust settings, and perform troubleshooting without complex training. Touchscreen panels and clear digital displays make the process more intuitive and efficient.

Safety features are equally important. Emergency stop buttons, protective covers, and automatic shutdown systems prevent accidents and protect both the machine and the operator. When a machine is designed with safety and ease of use in mind, it creates a better working environment and boosts operator confidence.

To maintain high product quality, modern laminated tube making machines include built-in inspection systems. These systems check each tube for visual defects, improper sealing, or uneven thickness. Automatic quality checks help detect problems early, reducing waste and ensuring only perfect tubes reach the packaging stage.

Some advanced machines use camera-based inspection systems to capture and analyze tube quality in real time. This ensures precise monitoring throughout the production process. Consistent quality control not only enhances brand reputation but also reduces production costs associated with defective items.

Even the best laminated tube making machine may require service or part replacements over time. Reliable after-sales support from the manufacturer ensures minimal downtime and quick problem resolution. It’s wise to choose a machine from a company known for providing technical assistance, training, and easy access to spare parts.

Having a dependable support team also guarantees that the machine stays in top condition for years. Regular updates, maintenance guidance, and spare part availability can make a significant difference in long-term performance. Businesses that consider after-sales support as part of their purchase decision tend to enjoy smoother, more efficient production.

Choosing the right laminated tube making machine is not just about speed or cost — it’s about quality, reliability, and long-term value. By focusing on features like automation, versatility, energy efficiency, and safety, businesses can ensure consistent performance and superior results. Each feature plays a vital role in creating durable, attractive, and defect-free tubes for different industries.

Before making a purchase, manufacturers should carefully evaluate the machine’s specifications, user interface, and support options. Investing in a well-designed machine enhances production quality, reduces waste, and improves overall profitability. A smart choice today can lead to years of smooth operation and satisfied customers.