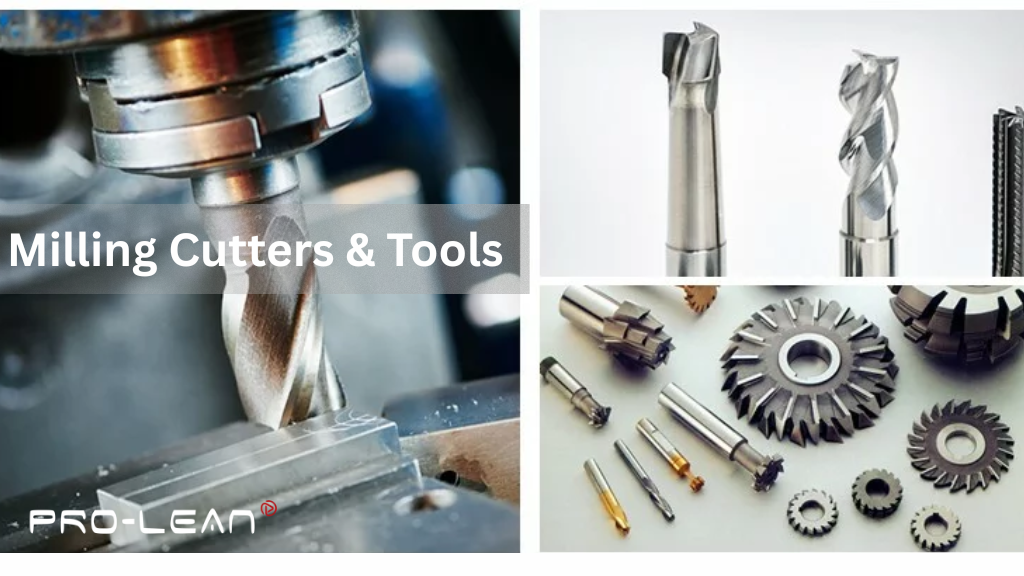

Milling cutters are the cutting tools made up of metal or carbide used in CNC machining. CNC machining is revolutionizing the manufacturing industry as it automates tasks, reduces manufacturing time, minimizes the risk of human errors, and increases the precision and performance of parts.

There is a process called CNC milling in CNC machining that works on the subtraction method, which makes parts by removing material from the workpiece. A milling cutter is a tool that holds great importance in the milling process. Selecting the right milling machine cutters ensures the best outcome for your end product.

So, let’s know the types of milling cutters, the materials used for them, and how they are revolutionizing the future of CNC machining.

Milling Cutters

Types of Milling Cutters

Milling cutters are of different types depending upon their shapes, sizes, and working capacity. In this section, we will discuss the types of cutting tools briefly. In order to choose the right milling cutter for your project, it's important to know about them firsthand.

An end mill is a rotary cutting tool that is used for multiple purposes in CNC machining. It has cutting edges on its sides and ends that help it to cut in multiple directions. End mills come in many different shapes and sizes and are used in a variety of tasks, including slotting, profiling, and contouring.

A face mill is a specialized milling tool possessing cutting edges on its face. It moves along its axis and is placed perpendicular to the workpiece. Face mills are primarily used to create the flat surfaces on large workpieces. It removes the material at high speed, but the speed can vary with the material being used.

ProleanTech provides you with high-quality milling services, as they have efficient milling cutters for a variety of materials and project sizes.

Cylindrical cutters are a general category of milling tools that are cylindrical in shape and have cutting teeth on their peripheral surface. They are placed parallel to the workpiece and specifically used to work on the large metal surfaces such as slabs and plates.

A ball cutter is a type of end mill cutter, typically called a ball nose end cutter. It has a rounded or hemispherical edge that is used to create the rounded shapes. It can be used on different materials, like metals, plastics and composites. The material used to make ball cutters is also based on their intended use.

A slab mill is a specific cylindrical milling machine cutter that is designed with high-speed steel. It is mostly used on broad flat surfaces to remove the large amounts of material quickly. Slab mills are commonly used in manual milling machines, as they can cut large surfaces at high speed.

As the name suggests, a side-and-face cutter is a milling cutter having cutting teeth on its sides and face. It has a dual working process and is used to create gears, keyways, slots, and gang milling.

An involute gear cutter is one of the types of gear cutters that are mounted in the milling machine and used to shape the metal workpiece into a gear.

Multi-point Fly Milling Cutter

A fly cutter is the rotary milling tool used to mill the large flat surfaces. Unlike the face mills, fly cutters possess a single or double cutting bit mounted on the spindle. It is placed perpendicular to the workspace. When the tool rotates, the cutting bit flies along its axis and creates shallow cuts on the surface of the metal.

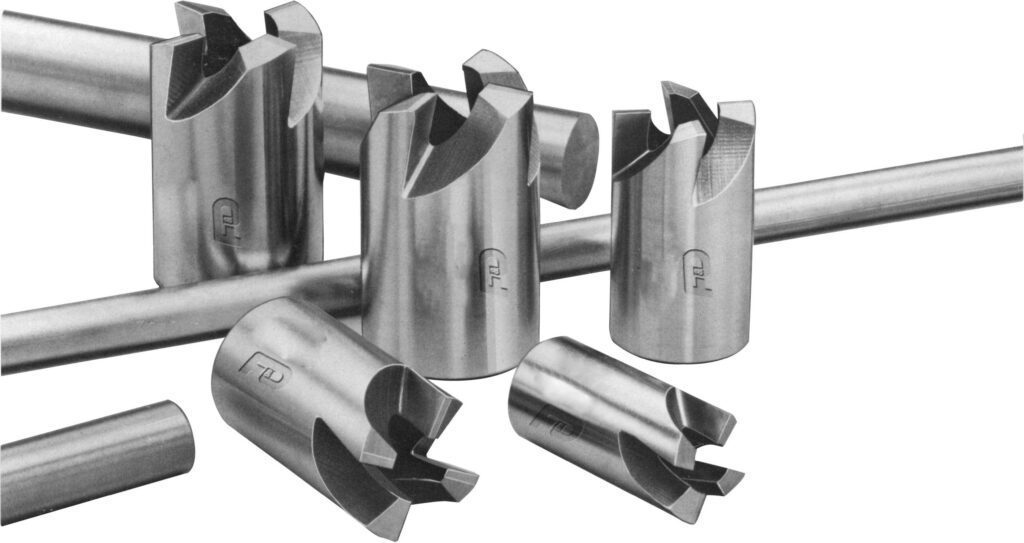

Hollow Cutters

A hollow mill is a tubular milling tool that has cutting teeth inside the hollow tube instead of on the outer surface like traditional milling tools. It is often called an inside-out end mill. This type of cutter is used in various operations such as grooving, turning, and facing.

Just like the variety in their shapes and structure, milling cutter tools can be made up of different materials. Some of them include:

Carbon steel is a cheaper and softer material used in milling tools. It is not so durable and is used in projects that require low-speed operations.

It is the type of tool steel that can endure high temperatures without losing its originality. This is the reason that it can be used in high-speed operational projects.

Cemented carbides are also used in making milling cutter tools. It is a harder material than high-speed steel, but its toughness is lower. That's why it is prone to cracks and wear and tear during the milling process.

Cutting ceramics is even harder but brittle than cemented carbides. It is also susceptible to wear and tear due to its low toughness.

CNC Milling tools are selected based on their material, diameter, coating used on them, number of flutes, and angle of helix. These parameters have an effect on the cost, durability, performance, and finishing of the end product.

Each material has its own strengths and features; knowing the requirements of your project can help you choose the tool with the suitable material. In general

Smaller tools manage fine details, while larger ones remove bulk more quickly.

Coatings like titanium nitride and others lessen wear and increase tool life.

Feed rate and material suitability are influenced by flute count and helix angle. More numbers of flutes result in higher feed rates, and steeper helix angles are suitable for softer metals and materials.

Milling cutters are essential to CNC machining, as the tool selection has a direct impact on the final product's speed, cost, durability, and quality. You can choose the best cutter for your project by being aware of the various kinds, their components, and their performance characteristics. Every tool, from sophisticated plasma cutters to conventional end mills, has a specific function. With the correct choice, your machining process brings accurate results, increased productivity, and long-term value.