Pendulum impact testers are fundamental instruments in material testing laboratories, used to determine how materials respond to sudden impact or shock loading. The device operates on a simple yet precise principle: a weighted pendulum swings from a fixed height and strikes a notched specimen, measuring the energy absorbed during fracture. This absorbed energy reflects the material’s ability to resist impact and deformation before breaking.

The method provides valuable insight into several mechanical properties, including impact toughness, strength, brittleness, and ductility. These characteristics reveal how a material behaves under rapid stress and are essential for predicting its reliability in real-world conditions. Because many engineering materials, especially metals and plastics, must perform safely under unexpected forces, impact testing remains a critical step in their evaluation.

Data gathered from pendulum impact testers guide industries that rely on strength and durability, such as aerospace, automotive, and energy. Understanding how much energy a material can absorb before failure helps engineers design components that maintain integrity under dynamic or low-temperature conditions.

In the following sections, this article examines three core topics: the key parameters measured by pendulum impact testers, why these results are vital for engineering and safety, and how equipment quality determines the precision and reliability of every test.

Pendulum impact testing provides several critical data points that describe how materials behave under sudden loading. The most fundamental parameter is impact energy, which represents the amount of energy a specimen absorbs before fracturing. This value, measured in joules, reflects the material’s capacity to withstand a shock without catastrophic failure. Higher absorbed energy generally indicates a tougher, more resilient material, while lower values reveal brittleness or poor toughness.

Another closely related metric is impact strength, sometimes referred to as toughness. It normalizes the absorbed energy by the specimen’s cross-sectional area, providing a standardized measure that allows engineers to compare materials of different sizes and shapes. Toughness defines how much deformation a material can endure before breaking, offering direct insight into its real-world durability under impact forces.

Equally important is the fracture behavior observed during testing. Pendulum impact testers help classify fractures as brittle, ductile, or transitional. A brittle fracture occurs suddenly with little plastic deformation, while a ductile fracture shows significant bending or elongation before separation. Many metals exhibit a ductile-to-brittle transition depending on temperature or composition—information that is essential for determining safe operating conditions.

The ductile-to-brittle transition temperature (DBTT) is a key indicator for materials used in low-temperature environments such as pipelines, bridges, or offshore platforms. By testing samples across various temperatures, engineers can identify the point where a material loses ductility and becomes prone to sudden fracture. Understanding this transition ensures that critical components remain safe even when exposed to cold or fluctuating conditions.

Impact testing data plays a decisive role in engineering because it reveals how materials behave under real-life, unpredictable forces. Components in the aerospace, automotive, and energy industries often face sudden impacts, vibration, or temperature changes. Knowing how much energy a material can absorb before failure allows engineers to predict its performance under extreme or accidental conditions. This knowledge directly translates into safer, more durable structures and products.

One major use of impact data is in evaluating welded joints and heat-treated components. Welding, cutting, and heat treatment can alter a material’s microstructure, potentially reducing its toughness. By performing pendulum impact tests on welded specimens, engineers determine whether joints will remain reliable under stress. Similarly, impact testing validates the integrity of parts that have undergone hardening or tempering processes, confirming that strength and ductility remain balanced.

Impact data also supports quality control and certification. Manufacturers use it to compare different material batches, detect inconsistencies, and verify compliance with technical specifications. In large-scale production, such as automotive manufacturing or pipeline fabrication, regular impact testing ensures that every batch of metal or polymer meets the same mechanical criteria. Without this verification, even small deviations could lead to structural weaknesses or premature failure.

In aerospace engineering, aluminum alloys are routinely tested for impact resistance to confirm their suitability for aircraft fuselages and wing structures. The same principle applies to high-strength steels used in transportation or construction, where toughness under low temperatures is crucial for preventing brittle fracture. Even in lighter industries, such as packaging, impact testing of polymers and composite films helps determine how materials will perform during shipping or high-speed manufacturing.

Beyond material qualification, impact test data often informs energy absorption design. Engineers rely on these results to develop components that can safely deform and dissipate energy during a collision or mechanical overload. This approach underpins the development of protective barriers, crash-resistant vehicle panels, and turbine components that withstand repeated dynamic loading. By analyzing absorbed energy and fracture modes, designers can fine-tune materials to achieve both strength and flexibility in critical zones.

The precision of pendulum impact equipment directly defines the credibility of the data it produces. Even though the principle behind these testers seems straightforward, accuracy in measurement depends on the mechanical stability and calibration of every component. The smallest variations in mass, impact velocity, or pendulum geometry can cause significant differences in recorded energy values, leading to unreliable conclusions about a material’s toughness or ductility.

For dependable results, a pendulum impact tester must maintain stable calibration, ensuring that the pendulum’s potential energy and striking speed remain consistent over time. A precise angle measurement system is equally vital, as the energy absorbed by a specimen is calculated from the difference between the pendulum’s initial and final swing angles. Additionally, controlled specimen clamping prevents unwanted movement during impact, guaranteeing that the energy loss corresponds only to material deformation and fracture. These combined factors define the level of accuracy that engineers can trust.

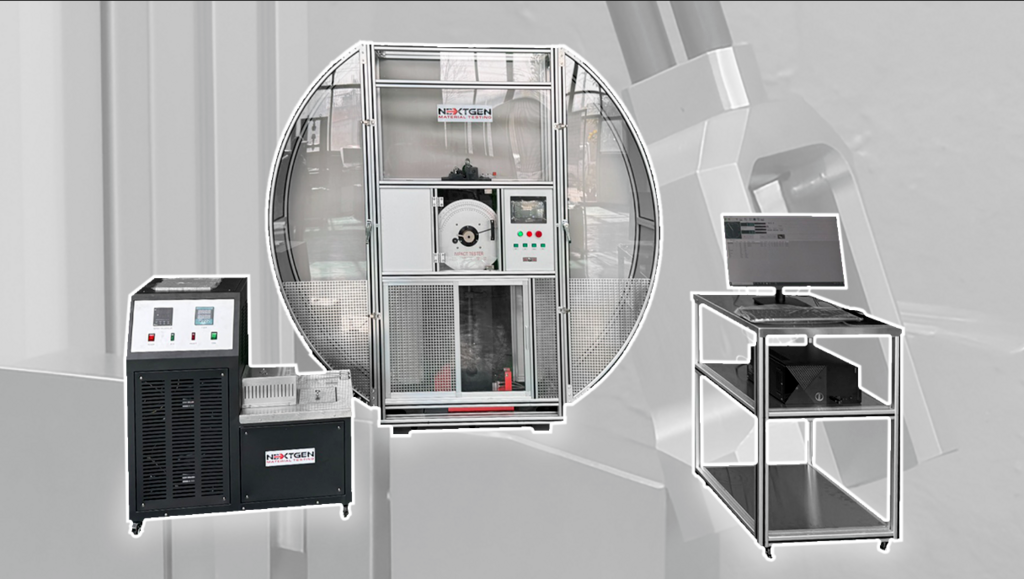

Modern equipment for metal testing, including Charpy and Izod impact testers, has evolved far beyond mechanical dials and manual readings. Contemporary systems now integrate digital sensors, high-speed data acquisition modules, and automated calibration routines. Such features enable laboratories to capture even subtle changes in impact energy and fracture behavior with exceptional repeatability. Advanced digital models also allow for automatic temperature compensation and software-based analysis, minimizing human error while improving testing speed.

Beyond precision, the reliability of pendulum impact testers depends on compliance with international standards such as ASTM E23, ISO 148-1, and DIN EN 10045. Standard-compliant machines guarantee that results can be compared across different laboratories and regions, maintaining uniformity in research and production.

Pendulum impact testers provide clear and measurable data on how materials absorb energy under dynamic loading. The results reveal key mechanical properties such as impact toughness, brittleness, and ductility, values that determine how a component will perform under shock or sudden stress. For materials used in demanding applications, these measurements form the foundation of structural safety and durability.

Reliable impact data allows engineers to design products that withstand unforeseen forces without sudden failure. It helps predict long-term behavior, optimize material selection, and refine manufacturing processes across industries from aerospace to metallurgy.

At the same time, consistent and precise data depend on the quality of the testing setup. Using high-grade equipment for metal testing, particularly calibrated pendulum impact testers, allows laboratories worldwide to obtain results that are comparable and reproducible. When the same standards and instrumentation are applied, the findings become universally meaningful and trustworthy.