Your drawings are flawless. You’ve double-checked the material specs, and the quotes look good. But weeks later, when you finally see the actual parts, they’re warped, off-tolerance, or rejected by QC.

Why? Because you treated cutting and machining methods as minor details—choices for your suppliers, not strategic design decisions.

If you’ve managed manufacturing, you know the real nightmare isn’t just overspending—it’s delayed launches, damaged client relationships, and endless cycles of rework. These are the hidden project killers that arise from overlooking seemingly small details in your cutting and machining strategies.

This guide will help you avoid these pitfalls by making better-informed choices right from the start.

Too many engineers and buyers assume cutting is straightforward—a basic step any supplier should handle easily. That assumption can quickly turn into costly reality checks. Here’s why your method matters:

Real example:

A European robotics startup laser-cut their aluminum enclosures for quick turnaround. The parts looked fine until anodizing revealed severe edge burning, resulting in 40% scrap, €12,000 wasted, and a six-week project delay. All could have been avoided by questioning the cutting choice at the start.

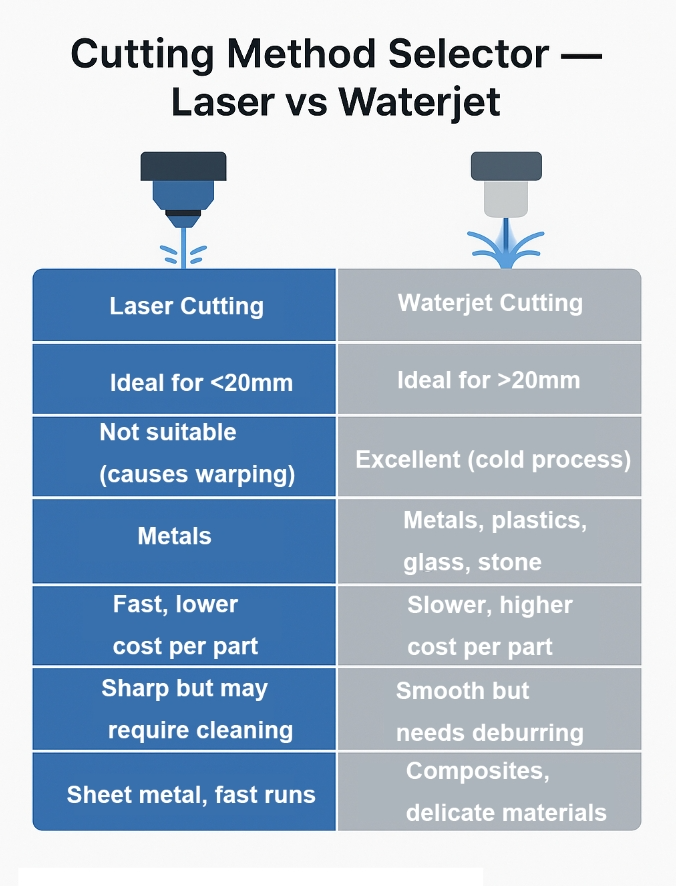

You’ve likely seen both options listed on quotes. But picking the wrong one—without understanding the actual trade-offs—can delay production, blow your budget, or compromise part quality.

Best for: Thin sheet metals (<20mm), high-volume runs, tight tolerances.

Caution: Heat can cause edge hardening or warping. Not ideal for laminated or composite materials.

Best for: Thick plates (>20mm), heat-sensitive materials (rubber, plastics, glass, stone), or composite layers.

Caution: Slower turnaround and higher cost per part; often requires extra edge finishing.

An automotive team defaulted to waterjet “to play it safe.” But their parts were thin aluminum sheets—perfectly suited for laser. The waterjet slowed down every production batch and pushed delivery back by nearly three weeks. That single decision added thousands to their budget.

| Project Requirement | Recommended Method |

|---|---|

| Fast delivery, thin metal sheets | Laser cutting |

| Heat-sensitive, laminated, or thick parts | Waterjet cutting |

| Ultra-high precision, delicate features | Waterjet + CNC finishing |

Still unsure? This practical overview of laser and waterjet cutting breaks down the use cases, pros, and pitfalls—so you can avoid expensive guesswork before sending out your next RFQ.

Too often, CNC machining is treated as a “nice-to-have” add-on. But here’s the truth: cutting shapes the outline—CNC gives you a finished, functional part.

If your part involves:

…then skipping CNC is like leaving your part half-built. Teams that try to get by with cutting alone often face QC failures, part rejection, or emergency re-machining—costing 3× more time and budget.

We’ve seen teams delay CNC, assuming they can “add it later.” But when cut-only parts fail to perform or fit during assembly, it’s usually too late. The result? Project delays, redesigns, and avoidable rework.

Aluminum alloys behave differently under the tool:

Choosing the wrong alloy—or using a supplier who doesn’t specialize in CNC for aluminum—can lead to dimensional issues, surface defects, or even part failure in-field.

If your project involves aluminum, start with the right partner. Explore our aluminum CNC machining services to ensure your design intent is matched by process precision.

Don’t send an RFQ without running your design through these quick questions:

Material:

Precision:

Surface & Finishing:

Volume & Timing:

Supplier Communication:

Design doesn’t end at the CAD model—it includes the manufacturing method. Your cutting choice directly determines production costs, lead times, and part reliability.

Ask yourself early:

Your suppliers won’t always proactively address these—it’s your responsibility to question, challenge, and clarify upfront.

Myth 1: “Laser is always cheaper.”

Myth 2: “CNC machining is only for large volumes.”

Myth 3: “Suppliers will optimize methods for me.”

The success of your project often hinges not on your design, but on how you bring that design to life. Misjudging your cutting or machining method is a silent project killer—one that can explode budgets, stretch timelines, and tarnish client relationships.

Here’s your immediate action item:

Before sending out your next RFQ, directly challenge your supplier using the checklist above. Don’t ask for a quote—ask for advice. The response may save your project.

Design smarter, ask better, and make decisions today that ensure project success tomorrow.

Manufacturing decisions aren’t supplier-only choices—they’re your strategic responsibilities. Get involved earlier, ask harder questions, and your parts will match your vision every time.