Lateral flow test kits are used across the entire world. This machine brings better accuracy and more reliable final products. They help companies produce more kits in less working time. This article explains how machines help make these tests better. Let’s explore the role of automation in test kit production.

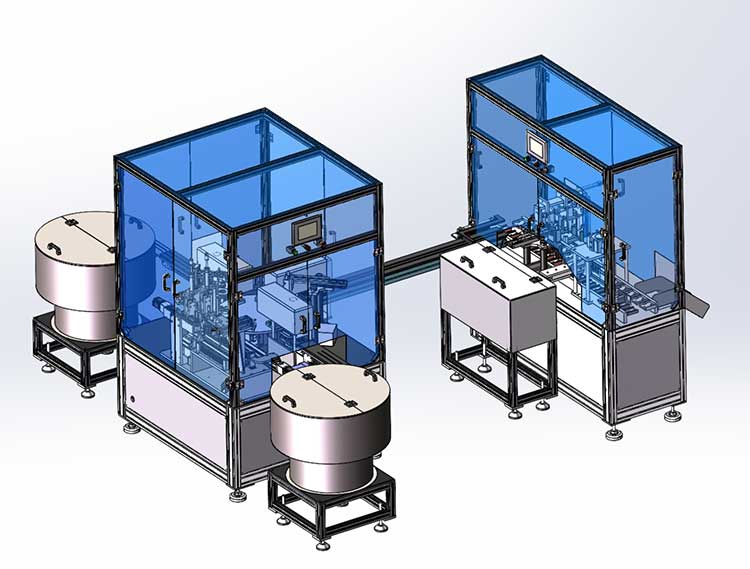

A rapid test kit assembly machine is a special device. It is used in factories that make lateral flow kits. The machine puts test parts together with speed and precision. It saves time and reduces human error in every step. This makes the production process faster, cleaner, and more organized. Each part of the kit is placed in the correct order.

Sensors and software help guide the process very accurately too. Using a rapid test kit assembly machine boosts output greatly. These machines are used in both small and large factories. They help companies meet global demand for test kits efficiently.

Automation offers many benefits in lateral flow test kit production. First, it saves time by working faster than human hands. Second, it reduces costs by lowering the need for labor. Third, it improves the quality of each test strip made.

The machine works without stopping and maintains stable working conditions daily. It also handles delicate materials with high care and precision. These benefits help make testing more affordable for more people worldwide. Automated production is becoming the new standard in test kit manufacturing.

The machine begins by feeding the base materials onto rollers. It places the sample pad where users drop their test liquid. Next, it adds the conjugate pad with special detection particles.

There are two types of machines: semi-automatic and fully automatic.

Fully automatic machines do everything without needing manual labor often. They work best in large factories with high production needs. Semi-automatic machines need some human help during certain production stages.

These are good for smaller companies or limited production runs. Both types improve speed and product quality over manual assembly. The choice depends on budget, factory size, and output goals. Each option offers a big upgrade from hand-made test kits. Companies choose machines based on their business scale and market demand. Both help streamline the making of lateral flow test strips.

The future of test kit manufacturing is smart and automated. More companies are moving toward machines for faster kit production. New machines now include artificial intelligence for better error detection. Smart sensors can adjust processes if something goes slightly wrong.

This ensures the highest level of quality every time produced. Larger volumes are made with fewer workers and less downtime daily. This helps lower prices and makes testing more accessible worldwide. Automation will only grow as health needs increase across regions. The rapid test kit assembly machine is key to this change. It is shaping the future of global diagnostic technology manufacturing.

Rapid test kits play a major role in global healthcare today. They must be made quickly, correctly, and in large quantities. Manual work is not enough to meet this growing demand. That’s why machines are now essential in making these test kits. They work fast, reduce mistakes, and lower production costs overall.

The use of a rapid test kit assembly machine helps. It ensures safe, reliable, and affordable testing for people everywhere. Automation is helping the medical world meet health challenges efficiently. The future of diagnostics depends on smart and scalable production systems. Machines are here to stay in lateral flow test manufacturing.

It is a machine that assembles lateral flow test kits.

Automation works faster than humans and reduces manual assembly time.

Yes, machines lower labor needs and reduce material waste costs.

Yes, fully automatic works independently; semi-automatic needs some human help.

They support colloidal gold and fluorescence immunochromatography assays.

It uses sensors and cameras to detect errors during production.