Factories don't just tinker anymore; they practically think for themselves now. Gigabytes of machine learning, IoT hooks, and cyber-physical guts are wired up, and the result is a production floor that feels half-alien, half-awesome. Stealing much of the spotlight, although it rarely gets a fanfare, is the crafty little photoelectric sensor.

By 2025, these light-waving workhorses have wormed their way into every corner of modern manufacturing. They spot slips, keep machines talking, and even forecast quits before a wrench can hit the floor. For any supplier chasing the cutting edge, stocking next-gen photoelectric tech has shifted from good idea to table-stakes demand. This post digs into why those sensors matter, what buyers should hunt for, and the spots where the payoff is obvious.

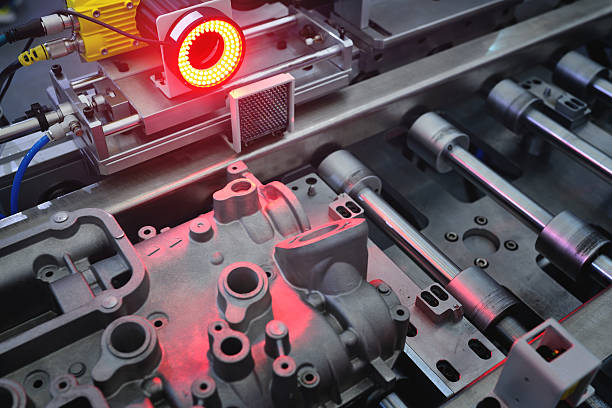

Photoelectric sensors blink without batteries on the object they watch, then decide if anything is there. A quick beam break or a light bounce triggers a silent shout-out that tells the main controller, Hey, look over here. That no-touch magic keeps messy fingers out of harm's way and lets machines move faster.

Photoelectric sensors show up in three main flavors.

Manufacturers pick one type over another based on how far away the target sits, if the surface is shiny or clear, and whether wind or fog might mess things up.

Modern factories crave lightning-fast feedback and constant motion without hiccups. Mechanical switches usually lag, so engineers swap them out for photoelectric units that register objects in the blink of an eye.

Because the sensors never actually touch what they watch, gears and springs sit idle, and routine fixes drop off the task list. The beams also skim over every imaginable surface-metal, plastic, glass, or paper-and even rope in invisible items that most gadgets ignore. Smart designers see those perks as non-negotiable in the high-speed plants of 2025.

Many photoelectric sensors can pick up an object several meters away. That extra reach comes in handy on enormous conveyor lines or under massive machines where walking back and forth would slow everyone down.

The best models react almost instantaneously when light breaks the beam. For factories running at breakneck speed, that split-second timing keeps the whole rhythm from falling apart.

Modern smart plants plug these sensors straight into PLCs, MES dashboards, and even cloud-analysis engines. Once the data moves through those layers, it can trigger maintenance alerts, update efficiency charts, or bootstrap other self-correcting routines.

Because they're small, tough, and surprisingly long-lived, photoelectric sensors have wormed their way into just about every automated process.

Practical Examples

Manufacturers lean on a solid industrial-automation-products supplier because sensors that fit these tasks and others keep production from stalling. The right technology goes a long way toward hitting daily targets.

Engineers and purchasing teams know the wrong sensor can sink an entire project, so picking a supplier is more than a numbers game. The real test is whether that partner understands the bigger picture and stands by the gear long after it ships.

1. Comprehensive Product Range

A one-size-fits-all catalog rarely cuts it. Buyers usually want through-beam, retro-reflective, and diffuse-reflective photoelectric sensors, each with different outputs and ranges.

2. Customization Capabilities

Manufacturing lines love quirks-adjustable ranges, special mountings, longer cables, or tougher enclosures. A flexible vendor will design or tweak gear to meet those unique specs.

3. Technical Support

Choosing the right sensor can feel like reading a novel in another language. Suppliers who offer clear wiring maps and hands-on tips save you hours and help dodge expensive mix-ups. If their engineers answer the phone without sounding harried, you've already cut project time in half.

4. Inventory Availability and Logistics

When the production floor is waiting, next-day delivery stops being a perk and becomes a lifeline. Extra credit goes to warehouses sprinkled across the country so parts land on your dock instead of a truck hauling them halfway up the coast. Zero stock is still the worst surprise in manufacturing.

5. Global Standards and Certification

Certificates gathering dust on a company wall won't keep a line running, but they do matter. CE, RoHS, and ISO stickers translate into less paperwork at customs and fewer safety meltdowns downstream. Every signature is a quiet promise that the gear will play nice with the world.

Smart factories don't just run harder; they talk to every piece of equipment in the room. By 2025 you'll find more photoelectric sensors packing IO-Link ports, handing back not just presence information but real-time health reports. That kind of chatter makes troubleshooting feel like rewinding a movie instead of shooting it again.

Modern photoelectric sensors go way beyond just clicking on or off. They now talk back with handy bits of information like

Because of this built-in brainpower, factories can start using predictive maintenance instead of waiting for things to break. Fewer surprises mean less downtime, and many plants appreciate being able to check thousands of sensors from one dashboard spread across all their lines or sites.

That tight data-link between advanced photoelectric sensors and the automation system suppliers who bundle them will matter more every year. Companies that can offer easy plug-together integration and designs that grow with demand will quickly move to the top of enterprise buyers' lists.

By now, any smart factory worth its badge leans on photoelectric sensors. Heading into 2025, the spotlight on this tech is brighter because manufacturers want more speed, sharper quality, and clearer performance numbers.

The sensors handle nearly any type of surface-plastic, metal, cardboard-while reaching both close up and farther away. That blend of versatility and reliability makes them key players in everything from robotic assembly lines to shipping inspections and floor-to-ceiling warehouse automation.

As the devices keep stacking on sharper features and better network hooks, their role in pushing Industry 4.0 forward will keep on growing.

Every factory manager knows that teaming up with a dependable industrial automation products supplier is the shortcut to pulling off photoelectric projects that actually save time and money. A trustworthy partner can turn a good idea into smooth-running machinery.

Pick the right sensing gear and the right vendor, and your shop will keep its edge even when competitors sprint past. In a world glued to real-time data, that cushion can feel like a full season ahead.