Pharmaceutical businesses depend on the delivery of accurate, dependable information to guarantee patient safety and preserve public confidence in medical systems. One of the significant features encountered in this process is the use of pill counters where pharmacists and manufacturers rely on to determine the right number of pills to dispense. He said that with the progress in the automation area in the pharmaceutical field, the equipment used as pill counters is equally advanced and precise. While reading this article, you will learn a basic understanding of what pill counters are and how they operate within the framework of pharmaceutical precision. This discussion also shows how pill counters depend on tablet press producers whose work involves the formulation of tablets that have to be accurately counted during the packaging process.

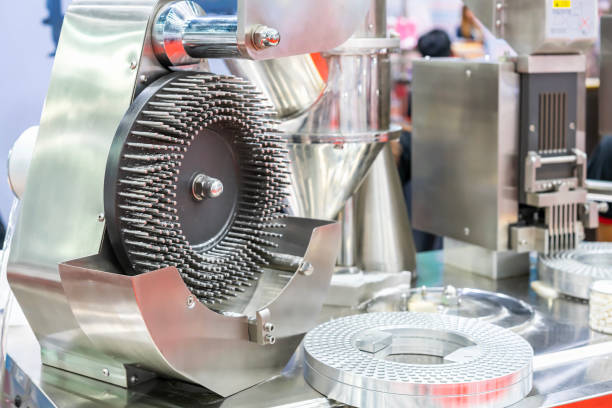

Pill counters are counting equipment that is a device that is used to accurately count tablets, capsules, and other pharmaceutical preparation forms. Earlier, the pill usage frequency was manually calculated, which, as is evident, is a herculean task ruled by elaborate human error and time wastage. Contemporary pill counters use a smart means to provide very accurate results in much less time than one could imagine taking counting pills manually. By employing the optical sensors, vibrating plates or infrared technology, these gadgets can work at an incredibly high speed to capture and determine the number of pills even being individual. Using these devices in tablet press productions are essential. There are several reasons that include identification of the number of pills available for packaging as well as confirming that the devices can pack the correct dosages to customers. Automated pill counting on one hand improves counting accuracy on the other hand improves product quality, and this is paramount in protecting patients, meeting the legal requirements and minimizing recalls.

Reducing, let alone eliminating, discrepancies in checking is crucial with regard to Dosimetric Quality Assurance and adherence to norms and requirements in the pharmaceutical sphere. The modern pill counting machines employ technologies, which include infrared sensor technology, where pill is weighed, or even image recognition Ai technology. They greatly reduce the probability of reporting high or low numbers that can cause dosage disparities with dangerous outcomes for patients. Thus, tablet press manufacturers and pharmacists can avoid human error during counting activities and guarantee the required dosage per container (which must meet safety indicators) and maintain the required quality of the medication dosage in patients. In addition, pill counters help to sustain package management to decrease cross contamination risks because the mechanical conveyor system in the robot insulates the product from additional direct contact from people to prevent specified pills from being conveyed only by the default.

Pill counters save time in the pharmaceutical operations and can be regarded as being more efficient for counting than the manual way. Counting by hand is very time consuming and may result in formation of bottlenecks especially when dealing with many quantities of drugs. While manual counters may take time and effort and be very exhausting, they can only count as many pills as one may physically force themselves to count, that is, it can take hours or even days to count thousands of pills, apart from the enormous costs that will be incurred to pay counter persons, automated pill counters can count thousands of pills in one minute. It is especially ideal for manufacturing plants, where interruptions in the counting process would inconvenience an entire manufacturing line. Also, semi automatic capsule machine and pill counters also at the time appear in a sequence to make a beautiful packing of the pills. Prompt delivery of pill counters can also help pharmaceutical firms meet production schedules, eliminate production constraints, and therefore, enhance their productivity so that their human resource can be devoted to other important quality control activities. Not only, it improves the effectiveness of operations, but also minimizes errors and improves work efficiency and market performances, leading to a discrete operation.

To the tablet press manufacturers, pill counters are important since they enhance quality of the pills and the compliance. Every container must hold the right number of tablets so that the actual count and manufacturing specifications meet the respective standards. Pill counters can be incorporated into lines of production helping to perform the counting whilst at the same time reducing wastage as each package will contain the required quantity. This accuracy is important to winning customers’ confidence as well as keeping a strict check on compliance with regulations. In addition, automation of the pill counters helps to minimize manual check-up with regards to the quality of the pills and therefore manufacturers can devote their time on formulation of the tablets, quality tests, etc. The usage of pill counters helps tablet press manufacturers improve their efficiency through decreasing their likelihood of recalls and increasing the dependability of the packaging. Besides the fact that manual errors negatively impact the quality of the final products, manufacturers can reduce risks to their reputation, and increase their competitiveness within the market which in turn enhances the quality of products that gets to the consumers.

Perhaps one of the most important tools in the pharmaceutical industry, counting machines are accurate, efficient and ensure quality in counting and packaging of pills. The available sorting options range from manual and semi-automated options to fully automated systems, and through them, all the needs of the industry can be met, and companies can choose the most suitable solution to their goals. Doing this, the designed pill counters minimize human influence and the time required for counting, which ultimately enables medications to be provided safely. Pill counters, alongside with technological instruments including a semi automatic capsule machine and tablet presses are effective aid to a more efficient, legal and safe pharmaceutical process relied on by the customers. To gain better efficiency in the pharmaceutical tablet press, manufacturers as well as other players in the market require to invest in improved tablet counter systems that increase the accuracy of the products, except for being capable of meeting set regulatory measures in order to ensure better patient safety and satisfaction . In the future with increasing operational complexity of pharmaceutical businesses, accurate and efficient pill counting solutions will continue to be essential to the industry’s commitment to providing safe, quality medications to customers, while driving efficient business growth for the future of the healthcare industry.